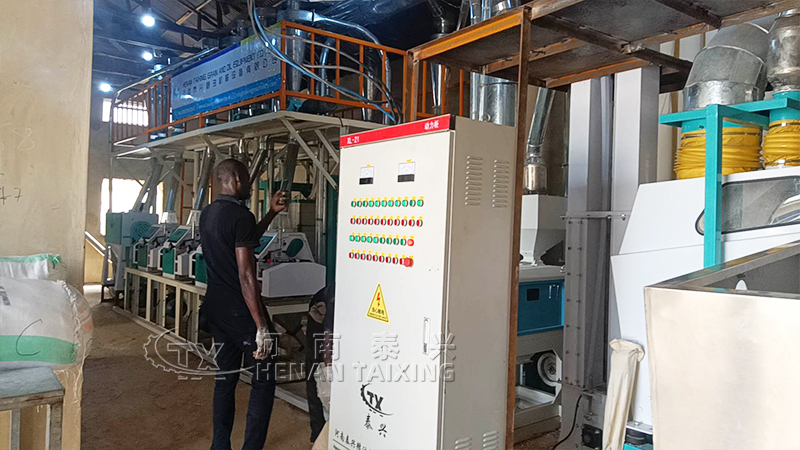

Project Name: 30 TPD Maize Flour Mill Machine

Country: Nigeria

Customer Background:

Customer Background:

Zero technical knowledge: He had no understanding of equipment or production processes.

Concerns about equipment reliability: He feared frequent breakdowns, turning the investment into "scrap metal."

Need for clear return on investment: With limited capital, he needed to know exactly how long it would take to become profitable.

Desire for a quick launch: He wanted to get his product to market as soon as possible

Our Solution: More Than Just Equipment—A "Starter Success Kit"

After deeply understanding our customer's needs, we did not simply sell standalone machines. Instead, we planned a complete "turnkey" startup solution for him.

1. Tailored Production Line Configuration:

Cleaning & Stoning Combination: Ensures clean corn flour even if raw materials contain minor impurities.

Efficient Degerming & Polishing Machine: Improves product appearance and taste, producing whiter, finer flour.

Fully Automatic Small-scale Milling Unit: The core equipment, known for stable operation and high flour extraction rate.

Integrated Electrical Control Cabinet: Simple operation with one-button start/stop, equipped with safety features.

2. Core Value Beyond the Equipment:

End-to-End Guidance from "0 to 1": Our engineers were responsible for on-site installation, commissioning, and hands-on training for our customer until they could independently produce qualified products.

Startup Mentorship: We shared operational experience from similar factories, including simple cost accounting, packaging suggestions, and market pricing strategies.

Reliability Commitment: The equipment was optimized for African power grids and climate, featuring robust construction and low failure rates. We provided a clear spare parts list and remote technical support to give him complete peace of mind.

Project Results: The Dream Becomes Reality

Rapid Production Launch: It took only 3 weeks from the equipment's arrival at the port to producing the first bag of qualified corn flour.

Stable Operation: The production line runs steadily for 8-10 hours daily, processing 20-25 tons of corn, fully meeting the designed capacity.

Market Success:

"Fresh, Local, High-Quality" became its biggest selling point. The corn flour was quickly purchased by surrounding residents, food stalls, and school canteens. Compared to imported products, his pricing was more competitive, and compared to traditional manual processing, his product offered superior quality and consistency.