If you want to start a maize milling business or a posho mill business in Kenya, South Africa, Zambia, etc. a well-considered business plan before you can begin milling maize into profitable maize flour, to avoid many investment risks.

Here are 5 tips to getting your maize milling business started:

1. Get financial support

Any business needs financial support before starting. How much does it cost to buy a flour mill? Do you need a loan or put all your money into this business. In order to estimate the amount, it is best to have a better understanding of the local market as well as the global market where the flour mill business is profitable.

2. Find a suitable factory location

Correct plant location is very important for flour mills. The correct factory location should have easy access to raw materials as well as delivery and shipping of the final packaged flour. Once the location is determined, it is time to leave the covered area of the flour mill. Generally speaking, a complete flour mill plant layout should include a raw material storage area, a flour mill area and a flour packaging area.

3. Obtain a milling license

Obtaining a license from the government or registering your mill with the local government is also important to the success of your flour milling business. Ensuring that every policy and flour production process complies with local regulations and regulations is an essential requirement for flour mills.

With the above conditions in place, it’s time to think about how and where to get flour machinery. The selection of flour mills is closely related to production capacity, investment cost, milling process, raw materials, etc., and cannot be done overnight. Therefore, it cannot be done overnight. Taking the time to choose the most reliable supplier of flour machinery can help avoid many unexpected problems in the installation and operation of a flour mill and reduce machinery procurement costs.

Types of Flour Processing Operations

Generally speaking, there are two types of flour mills: small and large. The choice should be between small or large scale depending on your specific situation. Below we will analyze small and large flour mills for your reference.

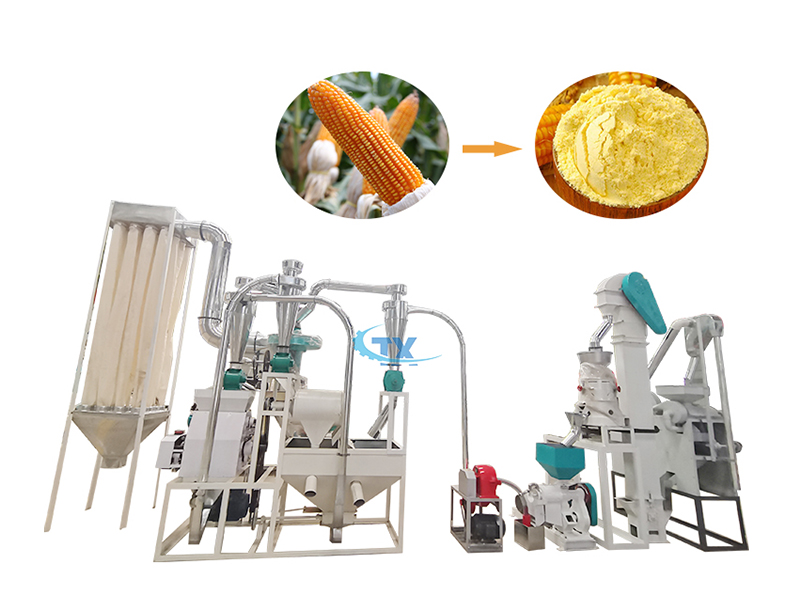

Small Business Flour Milling Plant

First, small-scale flour mill machinery requires very little capital, but has relatively small profit margins. It works well in two modes, one that charges a certain amount for milling and the other that produces flour. Therefore, the small flour mill business is very flexible and can adjust production according to market demands. The entire operation is also relatively simple and easy to use, and can be used by almost any adult.

Large Flour Milling PlantDue to the complex milling process and advanced milling machinery, large-scale investment in large-scale flour mill projects is inevitable. However, due to the large demand for wheat flour all over the world, especially in some regions such as India, Egypt, Algeria, Italy, Brazil, etc., in most cases, the profit is considerable. Large flour mills allow automated and continuous flour production from raw material to packaged flour.

5. Operator training and safety education

For most flour mills, flour production should have several operators or workers. Systematic training and safety education of workers and operators is one of the most important factors in starting a flour mill operation. Not only do they have to be proficient with equipment and machinery, but they also need to know how to add flour ingredients. Most four-mill suppliers offer training programs and courses to their customers to help them get into the flour industry quickly and avoid many typical operational mistakes.

If you want to start or extend your maize milling business plan, please contact us.

Services we offer as below:

1. Whole plant layout design.

2. Field installation, commissioning and training.

3. Supply quick-wear parts with machine when delivery.

4. Warranty: 12 months

5. After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service.