Wheat receiving and storage. In the acquisition of wheat, we shall pay strict attention to its quality, and store it separately in different warehouses according to their grade. The raw grain depot shall have proper ventilation, drying, anti rats, insect prevention and other measures.

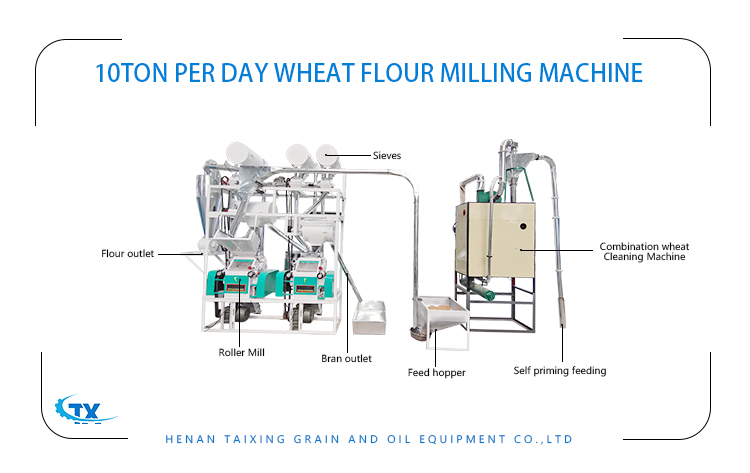

Wheat cleaning. When the wheat goes down the well, the pre-cleaner can remove large and heavy impurities first; then wheat goes into permanent magnetic drum for demagnetization. After that, the vibration sieve separates light and small impurities, while dry de-stoners finally clear away impurities similar to wheat size.

Wheat cleaning

Cleaning requirements

Dirt impurities shall be less than 0.3%, among which sand is not more than 0.03%, miscellaneous grain is less than 0.6%, and no metal impurities contained.

After the cleaning, ash content decrease shall be higher than 0.06%.

Net wheat moisture content shall make sure when produced, the flour water content meet with national standards.

The net wheat gluten contained in wheat should ensure when produced, the gluten value of flour meet the standards prescribed by the state.

Wheat flour milling (flour production)

Wheat flour milling (flour production)Bran milling: after grinding by bran mill, you get the mixture of cereal, slag pieces and coarse powder. The subsequent bran mill is responsible for scraping the coarse powder from bran.

After bran milling, the material is delivered into a square plansifter for screening, and the mixed material with different volumes are separated: a part of them are bran flakes that are delivered into bran mill for further grinding, a part of them is flour that will enter flour collection system, while the rest is a mixture of middling.

The mixture of middling needs to go into purifier for grading. After grading, some clean powder continues to be grinded, while the other part of the middling goes into core mill system for grinding. The core mill has 1-6path, which is in charge of grinding wheat core into flour with certain fineness.

Flour after checking, sieving and magnetic separation channel enters the packaging workshop.

Whereas bran after grinding enters bran brushing machine which separates the flour from bran, while bran enters outlet through the air duct.

Wheat flour production workshop requirements

Wheat flour production workshop requirementsThe flour milling workshop must be equipped with dust filtering equipment to prevent the dust in workshop exceed standard.

Before the wheat flour is delivered to packaging process, there must be magnetic separation equipment.

No chemicals unrelated to production are permitted to be placed in flour milling workshop, such as anti rat chemicals.

Before stepping into the workshop, anyone must wear clean work clothes, hats and shoes. No one is allowed to place personal clothing in the production area, or eat and drink, spitting, smoking in the production area.

All the processing equipment is added lubricating oil, workers shall clean up timely to prevent it from contacting with the product.

Shall set critical control point and formulate critical limit in accordance with production characteristics for such equipments like magnetic separator, additive trace feeder, etc. Formulate operation instruction for critical control point and fill in quality records.

Shall stipulate process inspection regulations according to the production characteristics of the project, and fill in quality records.

Shall formulate sub quality product control procedures, and take corrective measures when there is unqualified occurrence.

Packaging workshop

Through quantitative packaging machine, flour is packed into set weight according to customer needs, and then conveyed to sealing machine via a conveyor belt.

Finished products warehouse for wheat flour mill

The finished products must be stored in special warehouse. The ground needs a bedding material. The flour bags shall pile at least 3cm away from the wall. Do not store any objects unrelated to finished products storage or transportation.

The warehouse should have corresponding product symbol.

The warehouse should have rat proof and pest control measures.

The out-put or in-put of the finished product warehouse shall be recorded.

Transportation

All the transport vehicles, tools, bedding material and covering must be clean. It is not allowed to transport finished products and pollutants with the same car.

All the transport vehicles are not allowed to enter the finished product warehouse.